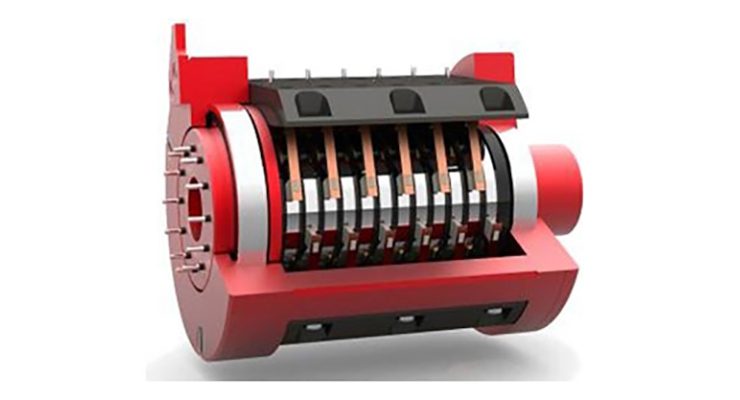

A slip ring commutator is an electromechanical tool. It allows the transmission of electrical signals and power from a device that is stationary to another device that is rotating. It is possible to use a slip ring commutator in any environment which requires rotation for the set up to transmit signals or power.

It improves the performance of mechanical parts in any machine while at the same time simplifying systems’ operation and reducing the wires which are prone to damages from getting in the way of moving parts. The rings have many names, including electrical rotary joints, swivels, collectors, rotating electrical connectors, and rotary electrical interfaces, among others.

(Guide) Slip Ring Commutator: Composition, Types, Alternative Uses & Names

Slip ring systems usually appear in AC alternators and systems. Some of the common systems which use slip ring commutator include wind turbines, cable reels, and packaging machines. Slip rings also have many uses in various sectors, including rotating tanks, heliostats, power shovels, digital and analog signals found in aerodrome beacons, control circuits, and other rotating objects, which transfer power.

The basic idea in a slip ring mechanism is to make an electrical connection with the use of a rotating assembly. Therefore, a slip ring commutator is an electric device that allows the flow of energy between two electrical parts, which are rotating just like a motor.

Composition: What is Slip Ring Commutator?

Usually, a slip ring consists of metal contact, otherwise known as a brush or stationary graphite. The purpose of the brush is to rub on the outer diameter of the rotating metal ring. When the circle turns, an electric current is generated; this is conducted through the unmoving brush to the metal ring, which makes a connection.

If there is a need for more electrical circuits, one can add extra brushes or rings in the system. The significant fact is that the ring or brushes should be stationary while the other parts move or the other way around. It is an original design that has been put to use for many years, and it has proven to be an effective way of passing current into a rotating device.

Alternative Uses & Names of Slip Ring Commutator –

Several other names refer to slip ring commutator, including electrical slip ring and rotary electrical contact, among others. Some people refer to the slip rings as just commutators. However, it is wise to note that commutators are different, and in most cases, they are used on generators and DC motors.

Another big difference between commutators and slip rings is that slip rings are continuous while commutators are segmented, and those terms and specifications are not interchangeable. In high speed or environments which require low friction, rotary transformers are used instead of using slip rings.

There are various ways in which slip rings can function within a rotary union. It is possible to use the slip ring concurrently with a device in such a way that it forms a rotary joint. To understand how it works, you should know that a slip ring has the same functions in terms of signal and electrical power, just like a rotary in fluid media.

Therefore, it is common to find slip rings integrated with rotary unions to send data and power to and from machines that are rotating together with the media, which is provided by the rotary union.

Types of Slip Rings –

Slip rings come in various shapes and sizes. It all depends on where the device will be of use. For instance, a device for use in theater has more than one hundred conductors. The main purpose of a slip ring is to give room for unlimited rotations to the object that is connected. On the other hand, you can only twist a slack cable several times before it starts to fail.

-

Mercury-Wetted Slip Rings:

Mercury-wetted slip rings are known for their stable connection and low resistance. The system uses a different principle, which involves replacing the sliding brushes with liquid metal, which is bonded to the contacts molecularly.

When the system is rotating, the liquid metal keeps the electrical connection active between the rotating contacts and the stationary contacts. There is a downside in using mercury-wetted slip rings because of safety.

Mercury is toxic, which makes the use of mercury-wetted slip rings in food, pharmaceutical, or medical industries a problem. In such industries, a leak could lead to severe contamination and a mortal threat to millions of lives.

Another problem associated with this type of slip ring is temperature because once mercury approaches -40 degrees Celsius, it begins to solidify.

-

Pancake Slip Rings:

They are called pancake slip rings because the conductors are arranged in such a way that they form concentric rings which are centered on the rotating shaft while lying on a flat disk. The configuration puts more volume and weight for the circuits, which in turn produces higher crosstalk and capacitance.

The system also has more significant wear on the brushes, and it readily collects the debris from the wear on its vertical axis.

The only downside with pancake slip rings design is that it reduces the axial length in the number of circuits. While it is a downside, it is also an advantage in some applications.

-

Wireless Slip Rings:

Wireless slip rings do not employ the friction method of carbon and metal brush to generate current like the other mentioned above. In this case, you can create data and power without any contact, and it takes place through the use of a magnetic field.

The stationary transmitter and the rotating receiver are responsible for generating the magnetic field. Wireless slip rings are an upgrade from the other slip rings since the lack of mechanical rotating parts implies that they can operate in harsh environments efficiently compared to traditional slip rings. The only downside with wireless slip rings is that the power transmitted between the coils is lower compared to traditional slip rings.

Final Thoughts:

Having been wondering what a slip ring commutator is? But with this guide, you have all the answers you need, including various types of slip ring commutators.

Moflon slip ring commutators have their uses in many aspects of our lives, and they fit in almost every application. Leave any questions or comment below.