Vacuum pumps are useful across many industries. For instance, they are crucial in the manufacturing of automobiles, airplanes, and even in the food processing industry. With such an essential role in multiple industries, vacuum pumps must get more efficient over time. Vacuum pump designers and manufacturers understand this and have continually made tech improvements to meet market demands. For context, here is how new technology is improving the efficiency of vacuum pumps.

(Guide) How New Technology Is Improving the Efficiency of Vacuum Pumps

-

It is making them More Energy Efficient –

We live in a world that is increasingly alive to the reality of climate change. At this point, there is near unanimity that renewable energy is the future of energy. That’s why in the last few decades, innovators have pushed hard towards energy-efficient technologies. The vacuum pump industry has not been left in this new wave of tech. For instance, there now exists some solar-powered vacuum pumps in the market. A company like Provac sells some of the best solar vacuum pumps in the market. You can search online for vacuum pumps provac sales and check out some of the solar-powered pumps they have for sale.

-

It is making them Smaller –

Due to advances in technology, it is now possible to make tiny, but very powerful gadgets. While this is most evident in the telecommunications industry, the vacuum pump industry hasn’t been left behind. Over the years, vacuum pumps have been getting smaller. The goal is to make them more efficient for use in industries where there are tight space requirements. Besides, reduced size also means that they consume less power. This makes them fully compatible with the energy conservation needs of this, and coming decades.

-

It is making them Easier to Maintain –

Over the years, manufacturers have eliminated the need for oil in vacuum pumps. This has made them much easier to maintain. Today, the average vacuum pump can go its entire life cycle without maintenance. For industries that rely heavily on vacuum pumps, this means a lower cost of operation. It also means that they can get more from the pump since it can operate non-stop for longer hours. These are improvements that technology has made possible for the pump market.

-

It has Enhanced its Performance –

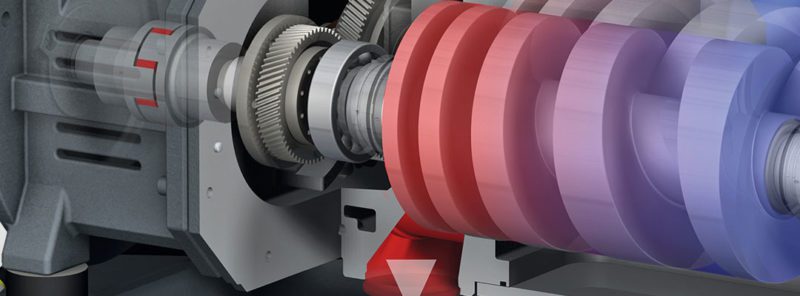

Technological advancement always comes with enhanced performance, and vacuum pumps are no exception. One way through which vacuum pumps have become better is in the working mechanism of their ball bearings. Nowadays, vacuum pumps use a technology known as the hybrid bearing system. This is simply a combination of the permanently magnetic radial bearing and ceramic ball bearing. The working mechanism is simple. The ceramic ball bearing works on the fore vacuum, while the permanently magnetic levitates on the higher vacuum side. It’s a tech development that eliminates wear and tear and gives the vacuum pump a longer functional life. It also enhances the speed at which the pump gets to work once activated. By extension, this means that manufacturers can get more out of their pumps, without adding to their operational costs.

![[Buy Now] YEPO 737A2 Review Notebook ‘Offer’ Price (Buying Guide) YEPO 737A2](https://www.techinpost.com/wp-content/uploads/2018/01/image001-12-324x235.png)

![[Buy Now] Anycubic PHOTON Complete 3D Printer Review ‘Offer’ Price Anycubic PHOTON](https://www.techinpost.com/wp-content/uploads/2018/02/2018-02-19_151248-324x235.png)

![[Buy Now] fnf Ifive Mini 4S Review Tablet PC “Offer” Price (Buying Guide) fnf Ifive Mini 4S](https://www.techinpost.com/wp-content/uploads/2018/01/thumb_60261_default_big-324x235.jpeg)