Gears play an important role in the movement of mechanical assemblies. Initially, it was started in china. Now, these gears are designed and implemented in every industry. Its applications can also be found in different sectors, from tiny clocks to heavy motor industries’ transmission apparatus.

With the introduction of new technology, gears are shifted to 3D-printed gears. 3D printed gears ease the way machines were used to live. 3D printed gears are not only very accessible but also very worthy. Using 3D-printed gears is always a good choice. Their flexibility is high because their parts can easily be replaced once manufactured. 3D printed gears are generally made of low friction, self-lubricating plastic printing material that makes these gears 50 times stronger than normal materials.

3D printed material offers indomitable wear resistance compared to other injection-molded components. One of the major benefits of using 3D-printed gears is they can be customized according to your requirements, including weight, shape, and transmission ratio. These 3D printed gears have a long service life with low wear and friction-optimized tooth shape. These gears can be easily shipped in 24 to 72 hours.

Gears have been used in different industries to design various objects that cannot be possible with traditional methods. Special attention should be paid to the designing process to prevent friction loss during power transmission. Materials used in gears play an important key role in the proper machinery flow. Traditional methods of designing gears have a limited scope and are very costly to produce. Another disadvantage of using traditional gears is that once they are designed, there have been several processes to customize traditional design.

3D-printed gears are very cool, and making them involves a lot of fun. But the question is how 3D printed gears manufacturers accomplish target results. Initially, gears used to be a meshing tooth used for rotation. The transfer of teeth is from one gear to another gear. Different size gears are used to alter the speed and torque.

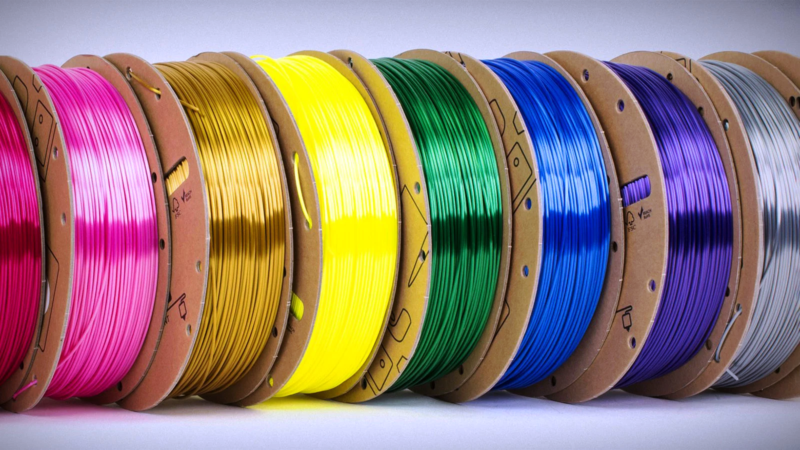

What Filaments are Best for 3D Printing Gears for Use in Industrial Applications

Plenty of 3D printing filaments are used to make 3D-printed gears for industrial applications. The filaments discussed below have their properties and behavior. Filaments like nylon, ABS, PLA, PETG, and many others are used for industrial applications. Many 3D printers available in the market come with a single type of filament. Still, if you want to color your hands with different types of filament, you must purchase a new one for other purposes, like printing gears.

To create 3D-printed gears, a selection of appropriate materials is necessary. The material for 3D printed gears depends on various factors like mechanical properties, including ease of printing, finish quality, and cost. This section will discuss which filaments are best for 3D printing gears for industrial utility. The filaments discussed below have pros as well as cons. Choosing filaments is all based on your needs or requirements.

Nylon

White color Nylon rope. Image source: Animated Knots

If you want something which is easy to print and should not be very brittle, then you should go with Nylon. Nylon is bioplastic and is made up of renewable sources. It is very smooth and silky and feels very smooth while printing. It is easy to touch, strong and flexible.

Due to its low friction coefficient and high melting temperature, Nylon is an ideal material for 3D printed gears. However, water can affect nylon because it can create problematic results. The leading cause of using extrusion printers is that nylon absorbs water like a sponge, swells, and makes all kinds of problems related to printing.

The main cause of defective nylon is that it absorbs moisture from the air. 1% and 4% water can cause material failure while printing, and almost 5% to 8% start absorbing 3D-printed parts. This will cause problems during the printing process and reduce the final product’s lifespan and make it unsuitable for outer uses. But Nylon is the best suitable 3D printing filament for 3D printing projects

for gears. It would be an excellent candidate for 3D printing gears.

PLA

Different colored PLA materials were placed on a table. Image source: All3DP

If you are in the 3D printing world, you must know about PLA. There are plenty of great things that can be proved about PLA. It is a low-cost 3D printing filament that comes under $20/kg per spool. It does not use a high printing temperature like ABS.

PLA is always a fantastic filament overall. With great flexibility and super strength, PLA is a much better material for gears than ABS and PETG, but not better than Nylon. Unfortunately, PLA is not apt for high temperatures because, during the summer, its material starts getting deformed.

So there are many factors to consider before purchasing any 3D filament. If you want to go with high temperature, then go with Nylon, but if not, use PLA for the low-temperature process; it will work wonders.

PETG

Red color PETG material wounded in a wheel. Image source: Amazon

Compared to ABS, PETG is a bit cheaper and much more expensive than PLA. Its expensiveness does not give competition to PLA and ABS. Both are good for some materials but are not the best choice for common gear design.

Although PETG is expensive, its versatility can’t be ignored. PETG is ductile and softer, with less scratch resistance than ABS and PLA. Nylon is hygroscopic, the same as PETG. Therefore, PETG requires needs to be pre-dried before any hard issues. The main weak point of using PETG is that it is brittle and has a lower glass transition temperature. PETG starts melting when the temperature goes to 80°C, whereas ABS has a unique quality in that it can tolerate temperatures upto 100°C; Nylon has excellent temperature resistance. It can easily bear temperatures upto 120°C.

PETG has not only temperature issues but also suffers many other issues. Therefore, it would be recommended for those who can afford it. Otherwise, you can go with Nylon and PLA.

After choosing a 3D printing material, you can use the best 3D slicer to prepare your design for 3D printing and then send the file generated through slicing to your 3D printer.

10 Best Interesting 3D Printable Gears

Planetary Reduction System

The Planetary Reduction System looks ridiculous, and it is pretty sure there is nothing to do with it, but we still placed it in position because of its cool look. You can easily print this most excellent 3D-printed gear using 3D printers. You can print this most excellent-looking 3D printed gear gives you the most expensive skill to print 3D printed gears. If you run out of money, you can use this gear for selling due to its attractive looks.

You can find the most excellent 3D-printed gears on Thingiverse.

Spool Holder

It is straightforward to design the 3D-printed gear. One can easily design the spool holder at home. The mechanism to make this Spool holder is very easy. Many users shared their experiences of how they made this 3D-printed gear quickly. If you need them, wheels can be easily resized, and you can download the file easily. You will find a manual guide on making the spool holder easily at home.

You can find this coolest 3D printed gear on Thingiverse

3D Printed Fidget Spinner

The 3D-printed Fidget spinner trend can’t be ignored. You can use planetary gears to design attractive 3D-printed gears. It has high torque, so it is best suitable to design a fidget spinner. The Fidget Spinner is used for entertainment purposes. With the help of a 3D printer, you can easily design and construct attractive 3D printable gears.

You can not completely 3D print the fidget spinner with the help of 3D printable gears. Although this is the simple version of planetary gear, it has drawn special attention from users.

Toy Robot Arm

Toy Robot Arm is one of the most fantastic 3D printable gears you have ever designed. You can easily use this 3D printed Toy Robot Arm for anything from lamps to a camera stand. It can print 0.2 mm layer height, but it will require some lubricant for the gears. Try this Toy robot arm to express your 3D printed gear skills.

NEMA 17 GearBox

NEMA 17 Gearbox is a functional 3D printed gear used as a tool. It is one of the best functional 3D printed gear that works as an existing stepper motor. This is a notable robotic arm, which is especially used for larger projects. The actual size of this gearbox is larger and very impressive.

You can find plenty of 3D-printed gear on Thingiverse.

Mechanical Clock

A clock is needed in every house. You can easily 3D print this gear at your home. The benefit of making this most excellent 3D printed gear is you will be on time if you make this very popular model, which would be an entirely 3D printed model. Also, it will make your home look classical. The winding mechanism requires nested planetary gears that allow the clock to run even while it is wound up.

Making the mechanical clock using the 3D printed gears can be very useful because the mechanism will continue even if it’s wound up. You can easily 3D print this object with the help of PLA because it does not require pins and screws in addition to the print itself.

Mask

If you want to generate nonfunctional 3D-printed gears, you can easily create this 3D-printed model. The model is especially for those who don’t want a functional planetary gear system for anything. It is one of the simple and 3D printed gear you can easily create for personal use. During and after the pandemic, the demand for this product was very high; with time, various designs were introduced into the market. Among them are very famous 3D printed masks.

It has two different planetary gear systems on each side of the mask. They are not functional, but their attractiveness greatly impacts users. You can 3D print this material with the help of a 3D printer in various steps, and the model can be 3D printed in different pieces and should be assembled after printing.

Gear Bearing

Easy to create. You can easily create a gear bearing. It can be easily disassembled once assembled. It is easy to change dimensions and can be easily adjusted.

Bowden Extruder

As we discussed above, planetary gears are very good at high torque. Therefore, you can apply 3D printing to make high torque Bowden extruder. This Bowden extruder increases its torque in a 5:1 ratio.

Water Motor

planetary gear systems have one problem a power source. The 3D printed gear water motor is a 3D printed concept device you can use running water to move the turbine. You can easily design these attractive 3D-printed gears for summer.